I recently coached some lean workshops in a large hospital. They weren’t part of an enterprise wide transformation but were three stand-alone activities which were all being run in parallel during the same week.

The facilitators and team members were great. All enthusiastic, willing to learn, willing to try new things and entirely committed to the process. Perhaps unsurprisingly the results were amazing.

Two of the teams worked on creating flow cells in their work areas to make their workplace more productive. Using the kind of things you’d expect in developing a flow cell such as visual management, 5S, flow etc. they were both able to create a much improved working environment which ultimately improved productivity. One team released 16% and the other 22% of their resource so that they could go and work on other important activities where they needed help.

The other team reduced the lead time in the supply of critical diagnostic results by 30% to 50% across the whole lab.

All this involved the team doing the work to improve the work, and some of the team actually proudly out-briefed the results to the senior leadership at the end of the week.

One of the clinicians in the audience at the end of week out-brief commented on the progress made in the lab lead time reduction. He reminded the team that when this particular process started many years previously it took up to 3 months to do just a fraction of their normal workload now. Their actions this week had now taken what was an acceptable 3 to 4 weeks lead time to just 10 to 14 days. I did say that the results were amazing.

Now what was it that made these results so achievable? I think this text already explains a lot of what’s needed. You need a reliable and robust improvement methodology, that we all know as Lean, and then you need a great team that is willing to learn, try new ways of working and not be put off when things get difficult. A team that understands why they are doing it, puts the customer at the heart of their decisions and truly believes that there is a better way.

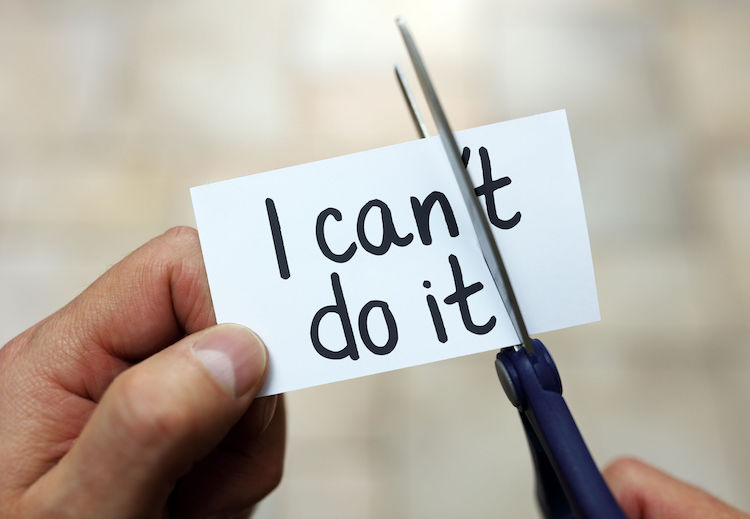

We have all experienced our fair share of naysayers and part of our role as coaches is to help them to see others ways of working. It’s not just about the application of lean tools it’s about the application of tools by the people who do the work.

The teams in this article definitely thought that ‘they can’, and I’m very proud to say that ‘they did’.

Photo Copyright: flynt / 123RF Stock Photo